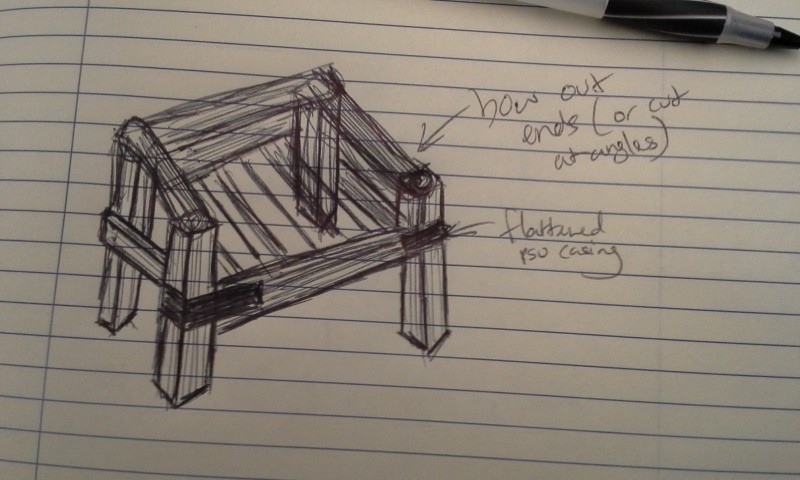

Or how I normally draw stuff before building.

The main thing I need to remember is I need to mange sure I have enough blocks to attach did to. I’m using some crap wood, so fancy attachments are out. I did learn my lesson from my apple press, in that dropping screws into the end of a board is a poor choice.

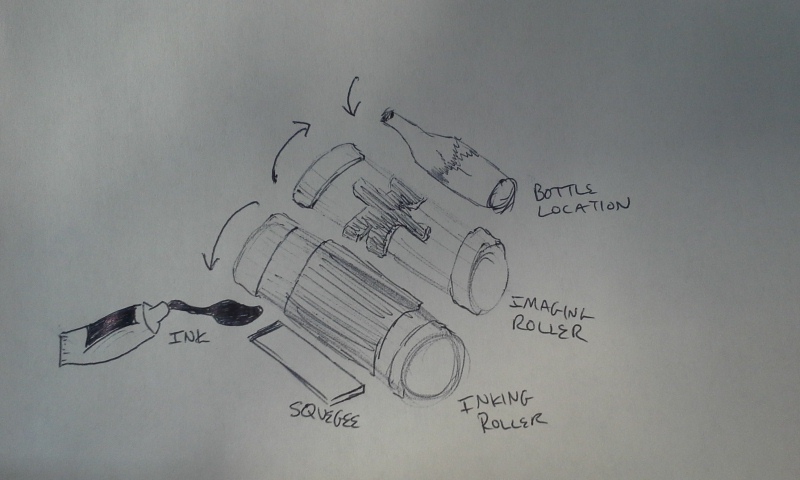

I think I should look at silk acting my own sketch books. Maybe hand bind them as well. Entirely custom workmanship to meet my irrational standards. Next time I go to an art store, I’ll have to look for and Diazo photo resist. Of course, once my bottle press is built, converting that print on paper shouldn’t be too hard.

Other notes include me wanting to increase the efficiency of brewing, both in regards to water conservation as well as heating. I don’t even want to think about much has was burned to boil water for a solid hour. A glass lid, a pressure gauge and a thermometer, all feeding days to control a hot plate weighs probably make everything better.